Dry Ice Impacting - An Environmental And Affordable System

Dry ice cleaning is a powerful cleaning method that aides in broadening the existence of gear while disposing of or diminishing the expensive substitution, fix, or rental projects. Dry ice cleaning is like other impacting methods like HP cleaning or sandblasting and varies just in the utilization of frozen CO2 strong pellets. On hitting the surface, the pellets sublimate, and the volume increments by multiple times. The evacuation of defiled surface layers comes about because of freezing, constriction, and debilitating. The utilization of dry ice cleaning gives impressive benefits on two levels. These are:

• As the dry ice pellets sway the surface, the top layer agreements and isolates effectively because of effect just as sharp cooling to - 78 degree centigrade coming about because of the CO2.

• The pre-owned CO2 is taken out without requiring treatment as it gets back to its vaporous state (sublimation of pellets in the air occur later there is impacting).

It is feasible to clean most of hardware in situ without requiring any destroying or trusting that the gear will chill off. The benefits that are accessible for this method include:

• Nature of creation improves

• No issues connected with wellbeing and security coming about because of poisonous solvents, along these lines making ready for a better workplace.

• Decreased work costs, cleaning time, expenses of fixing hardware, safeguard upkeep, and creation vacation.

• No development of stickiness. No development of optional waste, forestalling costs because of its expulsion.

• Less surface scraped spot, prompting an expansion of hardware life.

The utilization of delicate dry ice to strip away to surface disposes of the need to utilize hard rough items, as the dry ice is sped up to fast and structures a sort of smaller than usual blasts on a superficial level that prompts detachment of the undesirable components from the substrate.

There are great quantities of benefits to dry ice cleaning over the conventional impacting techniques. These are:

• The cleaning system is non-grating, non-conductive, and non-inflammable

• Natural and without presence of solvents and coarseness as auxiliary impurities

• Clean system, which is food industry supported

• No compelling reason to destroy a greater part of hardware; cleaning of greater part of articles should be possible in-situ

• The methodology could be performed without harming mechanical or electrical parts, the arrangement of fire hazards.

• It is feasible to eliminate striping specialists, creation deposits, oil and bio firms, paintwork, and impurities.

Applications

Cleaning processing plant establishments by dry ice impacting

The utilization of dry ice impacting for modern cleaning helps in extensive advantages as far as reserve funds to the business with plentiful decrease on schedule for cleaning molds for plastic, welding lines, electric engines, metal and PU parts, underlying components, fans, general and support upkeep.

Dry ice impacting reclamation

These days, with regards to post-fire cleaning, dry ice impacting administrations is the favored decision of method took on, as the sediment is wiped out and cleaning is caused on harm wear because of fire, rebuilding of memorable and evaluated structures, cleaning of veneers, reclamation of landmarks like frescoes, sculptures, expulsion of asbestos, buildup end, and de-pollution, development machines and gear cleaning, evacuation of biting gum.

Dry ice impacting of the creation line

Dry ice impacting procedure enjoys another benefit - the chance of computerization; the functional boundaries are set, while the cleaning was embraced is uniform, stable, and proficient, very speedy without requiring re-treatment of squanderer particles.

Dry ice impacting in the food business

Dry ice cleaning tracks down use in the agro-business in different areas like food and beverages creation, modern baking chocolate industry, expulsion cooking, pizzas and pasta creation, creature feed, prepared dinners, and so on The benefits found with this method include:

• Fast and productive techniques

• The cleaning methodology is dry and non-grating: there is no wear occurring while the article is being cleaned, and more prominent wellbeing of the electric gear.

• A natural and conservative methodology: no follows are left with dry ice, and there is no extra waste made that needs treatment

• There is a significant expansion underway because of the speed and effectiveness of the method s the cleaning is acted in-situ without requiring destroying/reassembly and no requirement for cooling, and so on

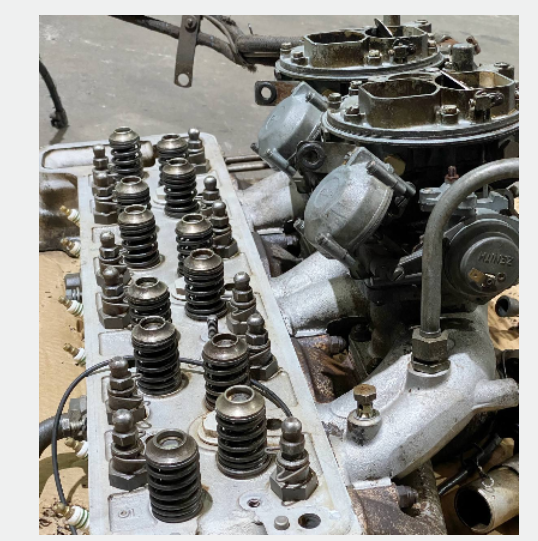

Dry ice impacting of electric parts

Dry ice cleaning is an unquestionable requirement have method for cleaning both high just as low voltage hardware like turbine, rotors and transformers, AC/DC engines, transformers and substations, atomic purification, electrical cupboards, and so forth

Modern support by dry ice impacting

Dry ice cleaning is generally utilized in different modern areas, particularly when the need is for support. The methodology is very effective all through the support work done on an establishment - previously, during, or a while later. It is feasible to clean while life and should be possible in all spaces in a productive and fast way.

The disadvantage of manual cleaning techniques is a deferral in endeavor the system because of stop closure of creation lines, while the standard media impacting strategies bring about the making of a bigger number of issues than settle. Dry ice impacting rental administrations is presented by Thompson Industrial Services, as they utilize dry ice impacting innovation that guarantees a cleaning arrangement that is fast, safe. Dry ice impacting cost is reasonable also, and helps in cleaning of hardware set up without requiring dismantling or chilling off. The utilization of non-rough carbon Dioxide in dry ice cleaning forestalls any sort of harms done to the surface or the hardware when utilized at sped up speed.

For More Info:-expert dry ice cleaning services Victoria

Comments

Post a Comment